Unblocking The Green Future

a lightweight, cost-efficient green building material revolutionizing construction worldwide. For the first time available in Bangladesh.

Years of Legacy

AAC Projects

Clients

What Is

NextBlock Autoclaved ?

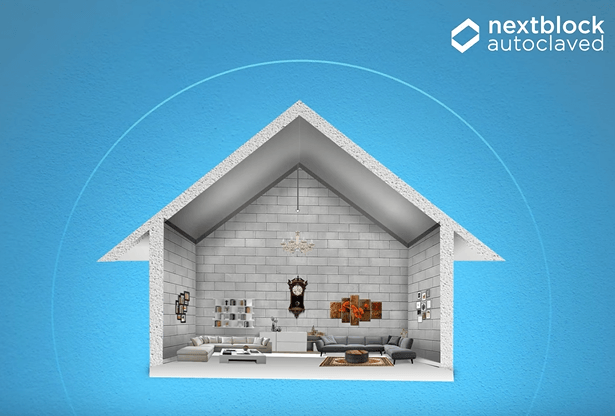

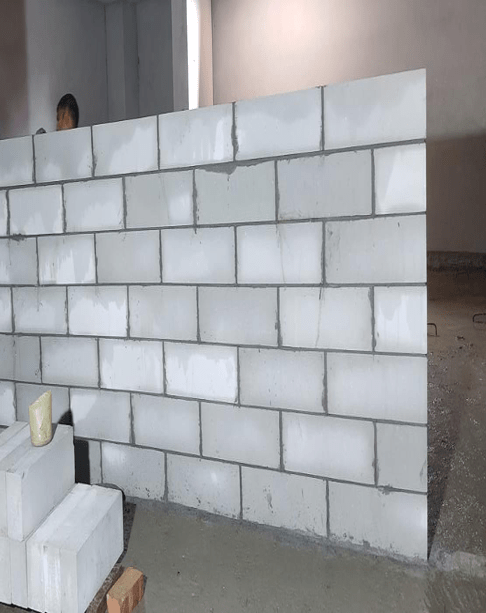

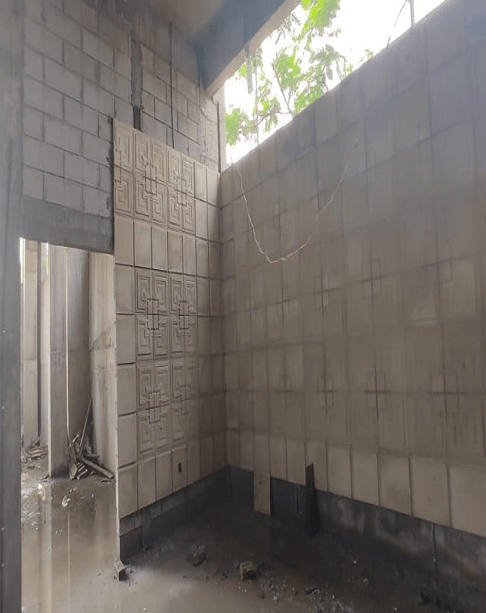

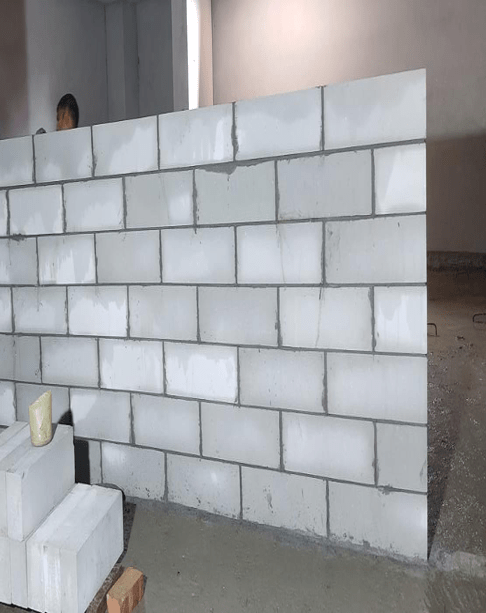

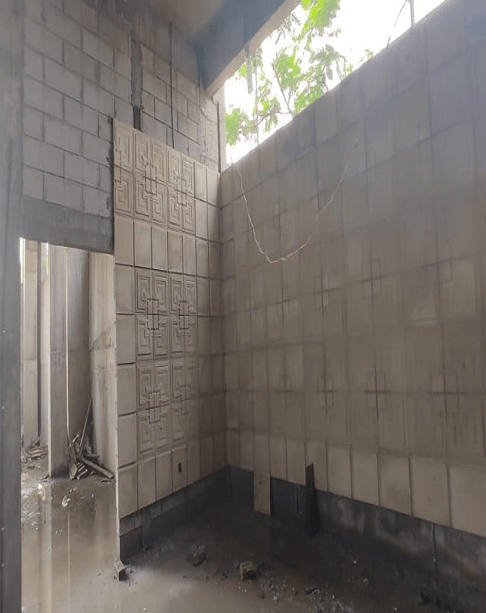

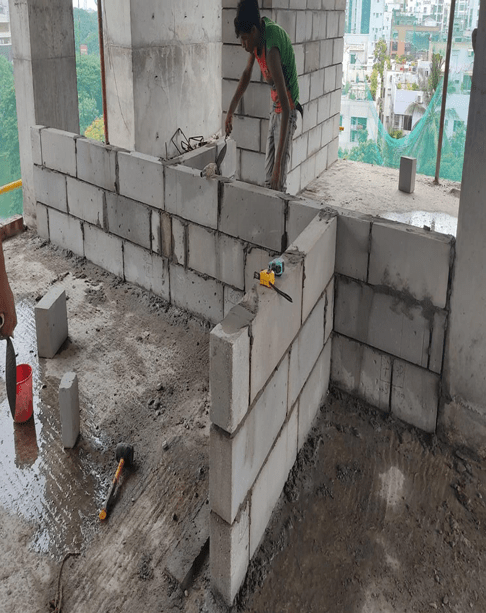

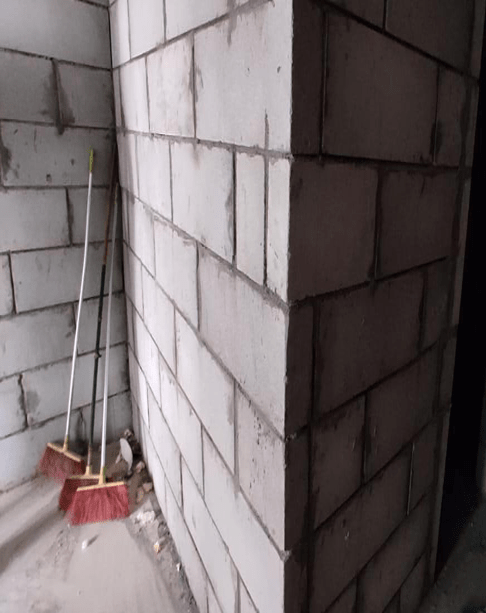

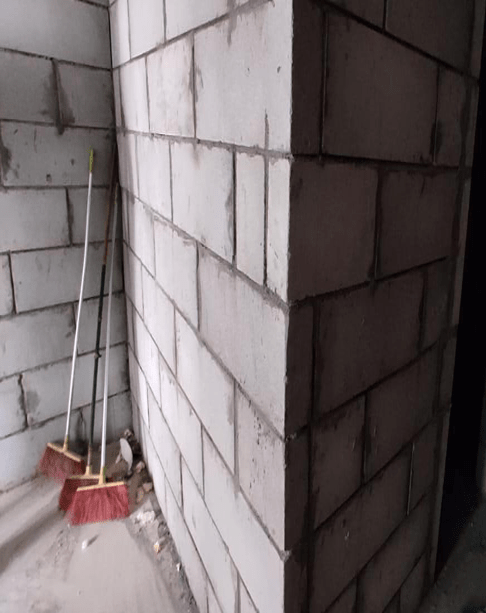

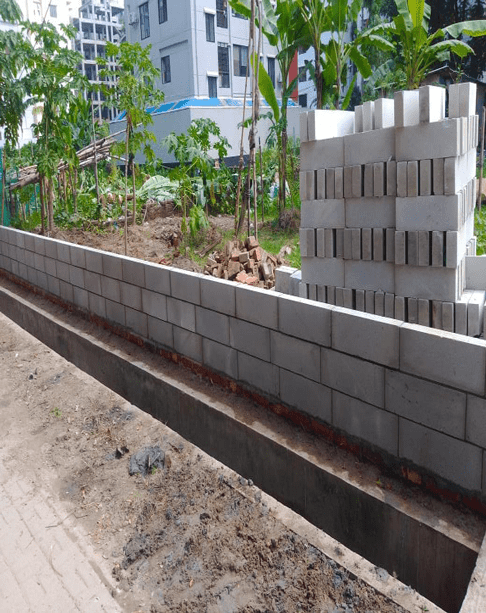

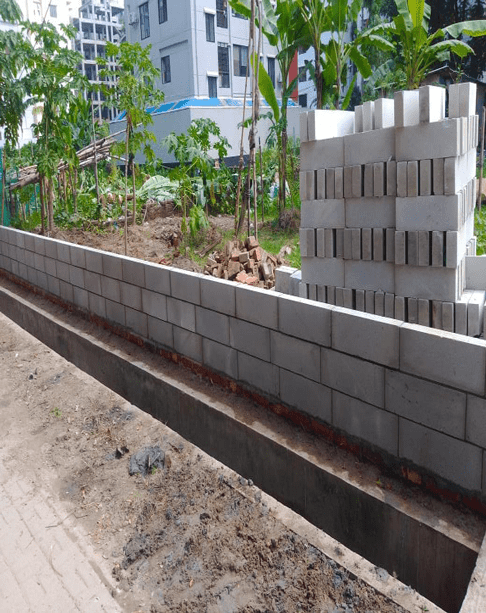

Nextblock-Autoclaved is the first Autoclaved Aerated Concrete (AAC) block manufacturer company in Bangladesh, specializing in the production of AAC blocks. This is considered as the best & finest solution for any kind of walls. It's an environmentally friendly, technologically advanced product that can replace all traditional bricks & blocks available in the market.

Swedish Innovation || German Technology

AAC was perfected in the mid-1920s by the Swedish architect and inventor, later developed in Germany. "Eco Friendly Green Bricks Ltd." a concern of "Tilottoma Bangla Group" introduced the AAC Block in Bangladesh jointly with technology partner "Chao Heng Investment Ltd.& their expertise from China. The factory is located in Tangail with yearly 156,000 cubic meter product capacity.

For over 70 years, AAC has been a trusted construction material with many advantages over traditional building materials.

Certificate

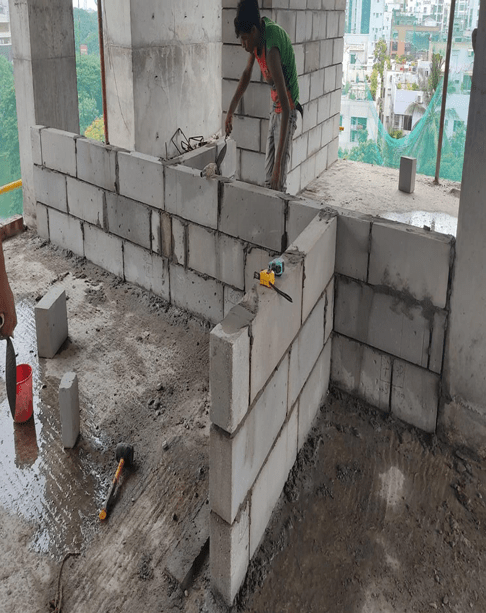

Faster & Easy Construction

Can increase the work speed into 2 times with easy installation

Certificate

Light-Weight

40% Lighter than Traditional Bricks . so it reduces the deadload of a building

Certificate

THERMAL INSULATION

Maintain Indoor Temperature, get advantage of 5 Degree Celsius in both Summer & Winter

Our Products

Explore Our Products

Choose Ultramodern AAC Blocks

Step 1

Ensure Faster Works

Step 2

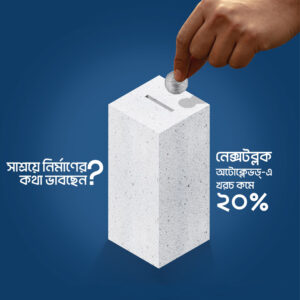

Save Money

Step 3

Get Technical Benefits

Step 4

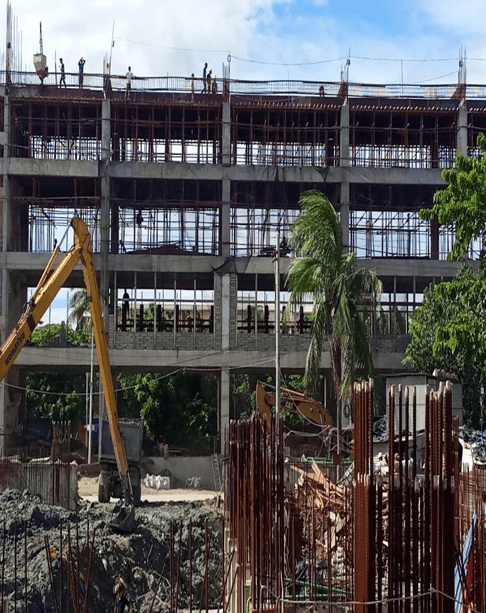

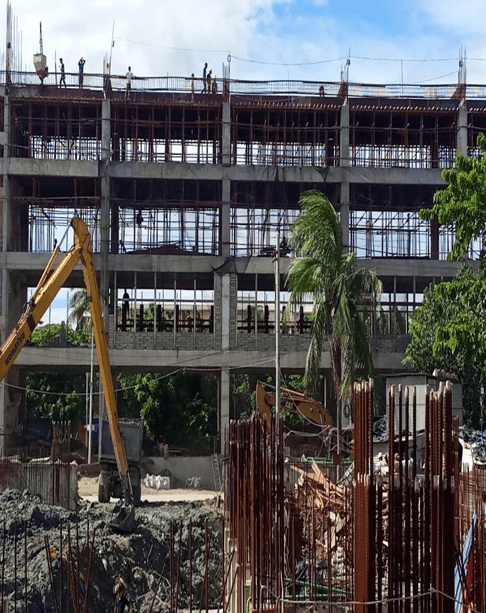

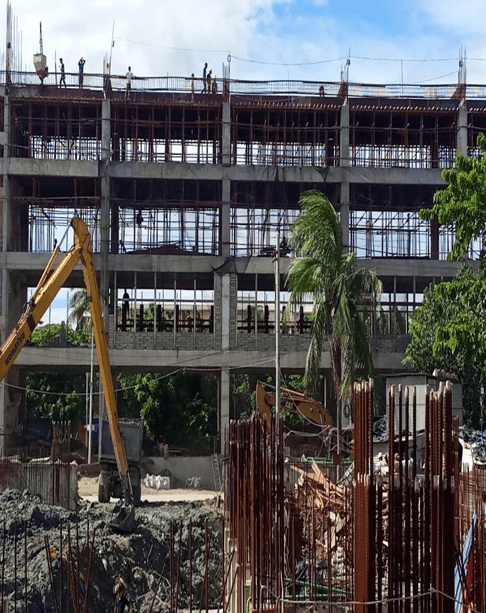

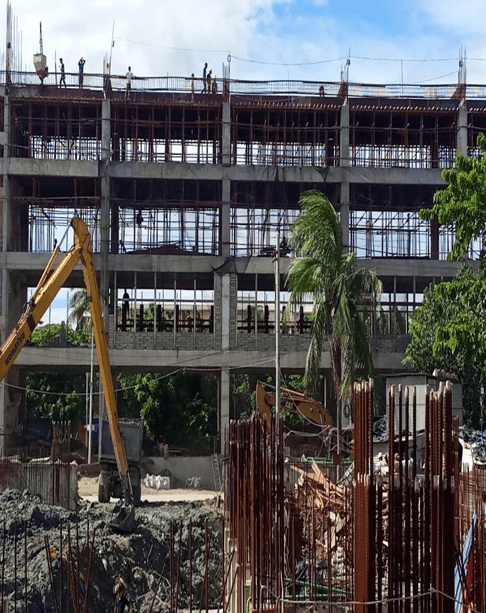

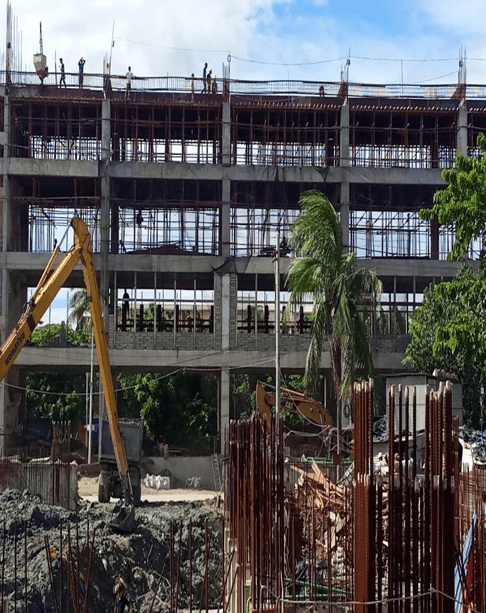

Our Mega Projects

United Group – United Tank Terminal

Anwara, Chittagong

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Purbachal-Rupganj,Narayanganj, Dhaka

Bashundhara Sports Complex

Bashundhara R/A, Dhaka

Rupayan City

Uttara, Dhaka

Q-Hotel, Quality Feeds Ltd

Purbachal, Dhaka

Pacific Jeans Ltd

Chittagong

United Group – United Tank Terminal

Anwara, Chittagong

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Purbachal-Rupganj,Narayanganj, Dhaka

Bashundhara Sports Complex

Bashundhara R/A, Dhaka

Rupayan City

Uttara, Dhaka

Q-Hotel, Quality Feeds Ltd

Purbachal, Dhaka

Pacific Jeans Ltd

Chittagong

3 Sign Engineering

Bashundhara

Tensile Architecture BD

Bashundhara

Bosoti Realestate

Khulna

DATASOFT

Madani Avenue

Ventura Properties Ltd

Dhanmondi

CDL-Residential Project

Uttara, Dhaka

3 Sign Engineering

Bashundhara

Tensile Architecture BD

Bashundhara

Bosoti Realestate

Khulna

DATASOFT

Madani Avenue

Ventura Properties Ltd

Dhanmondi

CDL-Residential Project

Uttara, Dhaka

Delvistaa

Gulshan

Sunflower Restaurant, Food Hall

Bashundhara R/A

Delvistaa

Gulshan

Sunflower Restaurant, Food Hall

Bashundhara R/A

Omni Properties Ltd

Bashundhara

Way Hotel

Uttara, Dhaka

Lakeshore Hotel Gulshan

Gulshan, Dhaka

Q-Hotel, Quality Feeds Ltd

Purbachal, Dhaka

Omni Properties Ltd

Bashundhara

Way Hotel

Uttara, Dhaka

Lakeshore Hotel Gulshan

Gulshan, Dhaka

Q-Hotel, Quality Feeds Ltd

Purbachal, Dhaka

Pacific Jeans Ltd

Chittagong

Cotton Field

Narayanganj

Krishibid Seed Limited

Gazipur

Bengal Hurricane Group

Gazipur

SAM Agro

Panchagarh

Pacific Jeans Ltd

Chittagong

Cotton Field

Narayanganj

Krishibid Seed Limited

Gazipur

Bengal Hurricane Group

Gazipur

SAM Agro

Panchagarh

Enam Medical College

Savar

Enam Medical College

Savar

Baitun Nur Central Mosque, Sagardighi Bazar

Ghatail, Tangail

Baitun Nur Central Mosque, Sagardighi Bazar

Ghatail, Tangail

Karnafuli Fish Meal Ltd

Gazipur

The Oasis, ABC Real-Estate

Mogbazar

Edison Real Estate

Ashulia

Cube Holding Ltd.

Bashundhara

Bashati Consortium Ltd.

Comilla

Karnafuli Fish Meal Ltd

Gazipur

The Oasis, ABC Real-Estate

Mogbazar

Edison Real Estate

Ashulia

Cube Holding Ltd.

Bashundhara

Bashati Consortium Ltd.

Comilla

CCDB – Climate Technology Park by NGO

Gazipur

United Group – United Tank Terminal

Anwara, Chittagong

United Group – IPCO Project

Airport

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Purbachal-Rupganj,Narayanganj, Dhaka

Bashundhara Sports Complex

Bashundhara R/A, Dhaka

Residential Project in Green Model Town

Motijheel

CCDB – Climate Technology Park by NGO

Gazipur

United Group – United Tank Terminal

Anwara, Chittagong

United Group – IPCO Project

Airport

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Purbachal-Rupganj,Narayanganj, Dhaka

Bashundhara Sports Complex

Bashundhara R/A, Dhaka

Residential Project in Green Model Town

Motijheel

Residential Project

Uttara

Residential Project

Mouchak, Gazipur

Residential Project in Green Model Town

Motijheel

Residential Project

Gazipur

Residential Project

Uttara

Residential Project

Mouchak, Gazipur

Residential Project in Green Model Town

Motijheel

Residential Project

Gazipur

United Group – United Tank Terminal

Anwara, Chittagong

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Purbachal-Rupganj,Narayanganj, Dhaka

Bashundhara Sports Complex

Bashundhara R/A, Dhaka

Rupayan City

Uttara, Dhaka

Q-Hotel, Quality Feeds Ltd

Purbachal, Dhaka

Pacific Jeans Ltd

Chittagong

United Group – United Tank Terminal

Anwara, Chittagong

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Purbachal-Rupganj,Narayanganj, Dhaka

Bashundhara Sports Complex

Bashundhara R/A, Dhaka

Rupayan City

Uttara, Dhaka

Q-Hotel, Quality Feeds Ltd

Purbachal, Dhaka

Pacific Jeans Ltd

Chittagong

We have an extensive network of distributors across Bangladesh. Our team will be happy to assist you in finding a distributor near you.

At NextBlock Autoclaved, we prioritize quality and ensure our products meet the highest standards.

এইচবিআরআই ও নেক্সটব্লক অটোক্লেভডের চুক্তি

এইচবিআরআই ও নেক্সটব্লক অটোক্লেভড চুক্তি সাক্ষর

পরিবেশবান্ধব এএসি ব্লক উৎপাদনে সমঝোতা

Nextblock: Building material for the next generation

Eco Friendly Green Bricks wins ‘Best Process Innovation’ award

Get a Quote

Build Your Future Today

Let's revolutionize the construction industry and shape a better world for future generations. Choose Nextblock-Autoclaved and build your future today.

- Choose Ultramodern AAC Blocks

- Ensure Faster Works

- Save Money

- Get Technical Benefits

Request A Quote

I appreciate your interest in Nextblock-Autoclaved. Our team will respond to you at the earliest possible time. To request a quote, kindly provide us with the following information:

Contact Info

Our Location

House: 26 (Ground Floor), Road: 07, Block: G, Banani, Dhaka -1213, Bangladesh

Quick Contact

- Call Us : 01321206780

- Email : info@nextblock.build

Opening Hours

- Saturday to Thursday

- 10.00 am to 6.00 pm

Do You Have Any Question, Just Contact Us To Get Help!

Reviews

What people says about Golobe facilities