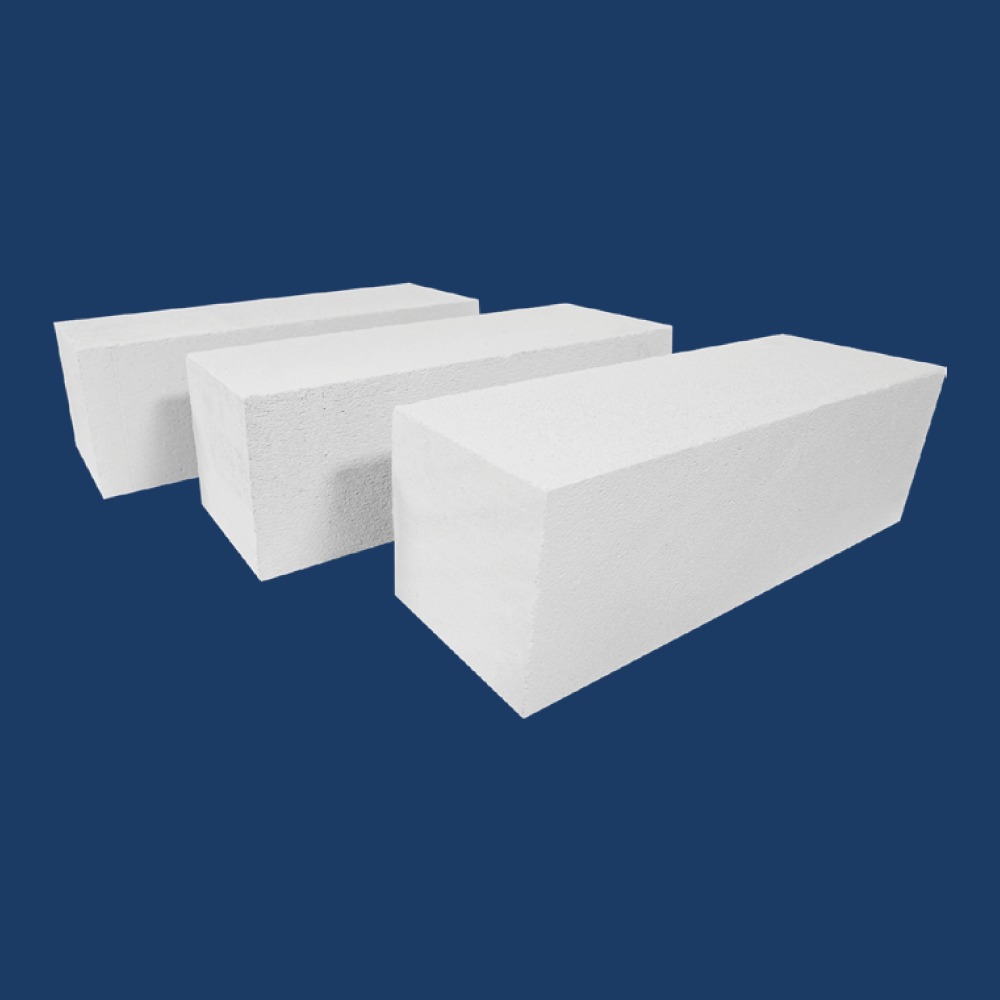

AAC Block

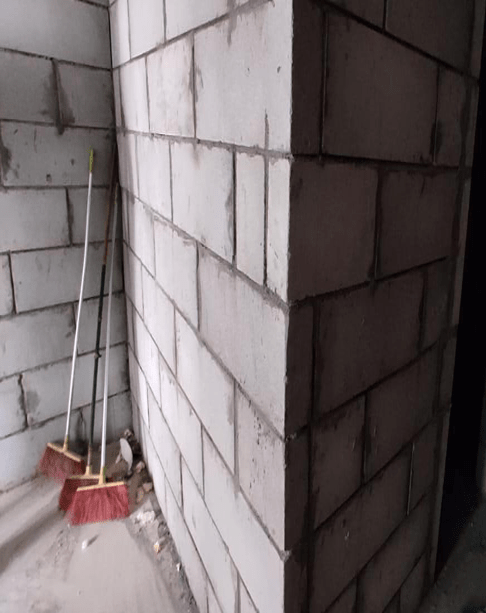

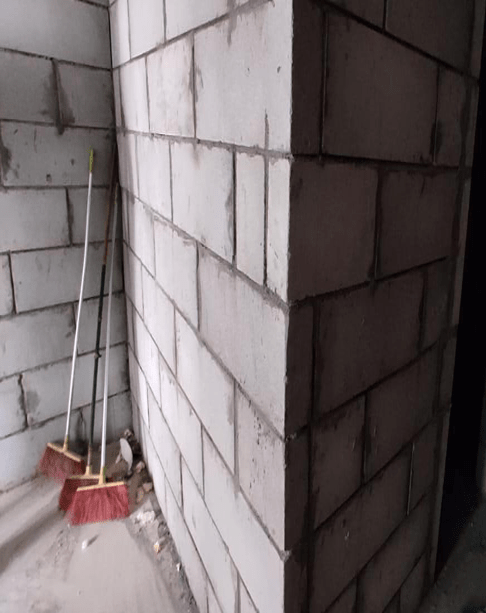

The AAC block’s basic raw material is sand added with cement, lime, gypsum, aluminum powder & other additives. It’s a non-loadbearing masonry unit which is best for any Kind of wall solution. Choose our high-quality AAC blocks for your next construction project and participate in the green revolution.

Years of Legacy

AAC Projects

Clients

Features & Advantages

For being a technologically advanced product, Nextblock-AAC is offering some fundamental features & advantages to its users.

Certificate

Faster & Easy Construction

Can increase the work speed into 2 times with easy installation

Certificate

Light-Weight

40% Lighter than Traditional Bricks . so it reduces the deadload of a building

Certificate

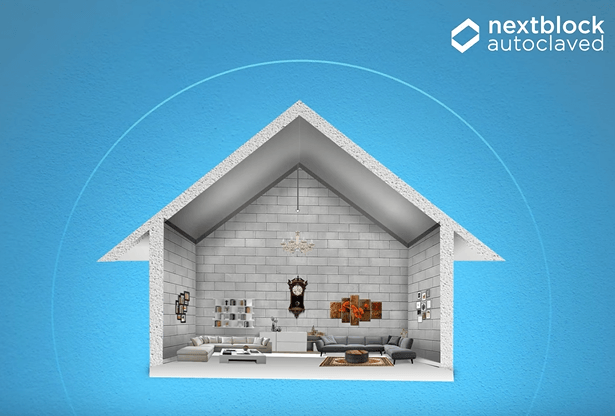

THERMAL INSULATION

Maintain Indoor Temperature, get advantage of 5 Degree Celsius in both Summer & Winter

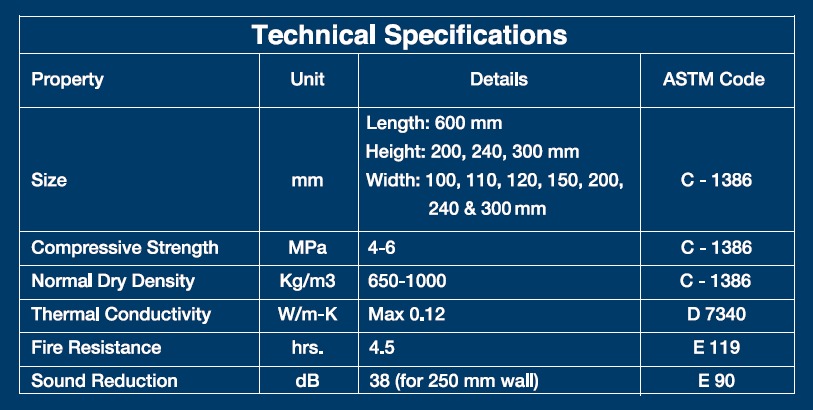

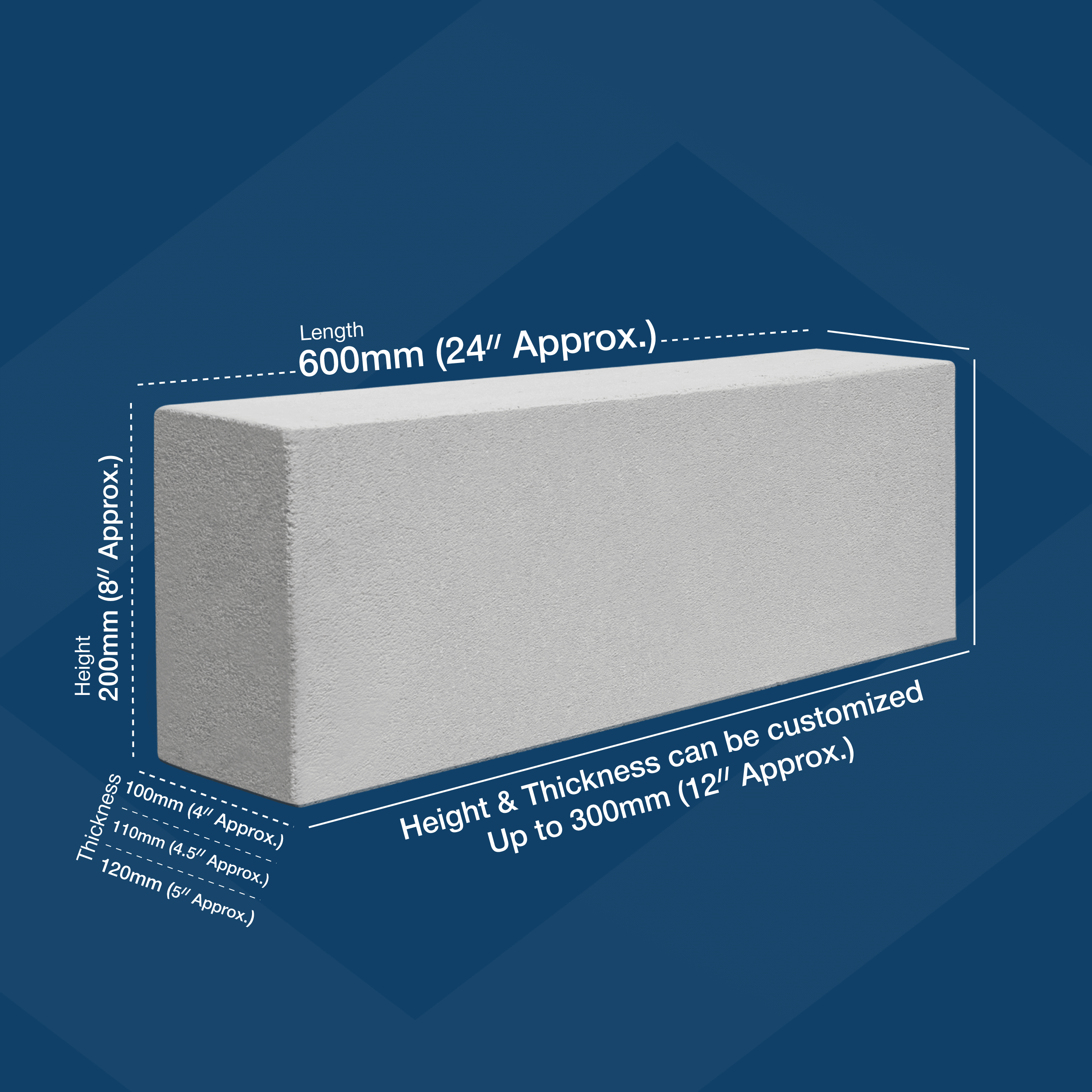

Product Size & Specifications

Our AAC blocks come in various sizes to suit different construction needs. Standard sizes include 600x200x100mm, 600x200x150mm, and 600x200x200mm. Custom sizes can also be provided as per customer requirements.

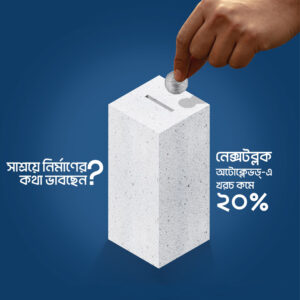

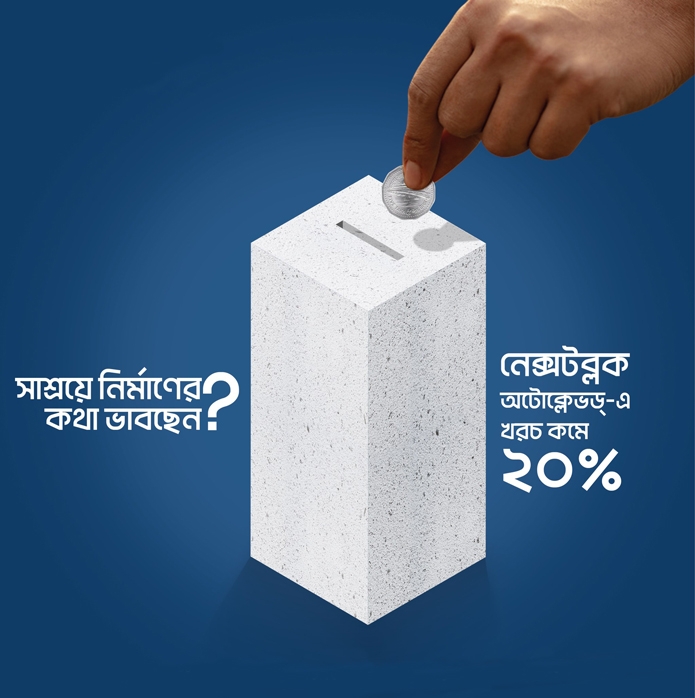

How Do AAC Blocks Save cost?

Using AAC blocks can reduce overall construction cost up to 20%

- AAC blocks are very affordable in price

- For being light-weight AAC blocks reduce foundation cost

- One AAC block is equivalent of 7 red bricks in size, so it reduces the joint mortar cost

- For being large in size it makes work 2 times faster, saves labor cost

- AAC blocks reduce cement & steel consumption in construction

- The excellent thermal insulation properties of AAC blocks also result in energy savings, reducing long-term operational costs.

Comparison For 100 sft Wall

AAC Block Application Guide

Learn how to effectively use AAC blocks for various construction applications. Our guide provides step-by-step instructions and best practices for optimal results.

Drilling & Necessary Installments on AAC Block Wall

Watch and Learn how easy it is to install anything on AAC Block’s wall.

Our Mega Projects

Discover the impressive construction ventures we have undertaken, showcasing our expertise and commitment to excellence in the industry.

Remarkable

Factory Industry

Residential Developer & Corporate Clients

Residential Individual Clients

Hotel

Boundary Wall

Others

Bashundhara Public School & College, Bashundhara R/A, Dhaka

United Group – United Tank Terminal, Anwara, Chittagong

Hotel-The Way Dhaka Living, Uttara, Dhaka

Felicity Big Data Center (Software Technology Park), Jessore

Rampal Power Plant, Bagerhat, Khulna

Japan-Bangladesh Friendship Retirement Homes (AWR & CPDL), Purbachal-Rupganj,Narayanganj, Dhaka

Bangladesh Auto Industries Ltd., Mirsorai Economic Zone

Hotel-The Way Dhaka Living, Uttara, Dhaka

United Group – United Tank Terminal, Anwara, Chittagong

Bashundhara Public School & College, Bashundhara R/A, Dhaka

Bangladesh Auto Industries Ltd., Mirsorai Economic Zone

Japan-Bangladesh Friendship Retirement Homes (AWR & CPDL), Purbachal-Rupganj,Narayanganj, Dhaka

Rampal Power Plant, Bagerhat, Khulna

Sadma Group, Gazipur

Rapita Shoe Factory by Fortis Group, Gazipur

Akij Glass Factory, (Akij Bashir Group), Sylhet

Pacific Jeans Ltd. & Pacific Attire Ltd., Chittagong

Sadma Group, Gazipur

Rapita Shoe Factory by Fortis Group, Gazipur

Akij Glass Factory, (Akij Bashir Group), Sylhet

Pacific Jeans Ltd. & Pacific Attire Ltd., Chittagong

Some Complete Residential Projects of Individual Clients

Rajbari Holdings, Bashundhara R/A

Rupayan City, Uttara, Dhaka

Al-Aksha Developers (Pvt) Ltd., Rajshahi (AAC Blocks as Heat Proofing Solution at the Rooftop)

Momen Real Estates Ltd., Dhaka

Janani Builders Project, Keraniganj

BDDL Properties Ltd., Dhanmondi, Dhaka

Bay Developments Ltd.

RANKS FC, Chittagong

Sanmar Properties Ltd., Chittagong

Edison Real Estates Ltd., Bashundhara R/A, Dhaka

Some Complete Residential Projects of Individual Clients

Rajbari Holdings, Bashundhara R/A

Rupayan City, Uttara, Dhaka

Al-Aksha Developers (Pvt) Ltd., Rajshahi (AAC Blocks as Heat Proofing Solution at the Rooftop)

Momen Real Estates Ltd., Dhaka

Janani Builders Project, Keraniganj

Individual Project by Maison’D Architects at Manikganj

Residential Project, Sylhet

Residential Project, Uttara

10 Storied Residential Project, Dakkhinkhan, Uttara

10 Storied Residential Project (5000 sft), Bhuighar, Naryanganj

Individual Project by Maison’D Architects at Manikganj

Residential Project, Sylhet

Residential Project, Uttara

10 Storied Residential Project, Dakkhinkhan, Uttara

10 Storied Residential Project (5000 sft), Bhuighar, Naryanganj

Lakeshore Hotel Gulshan, Dhaka

Omni Properties Ltd., Banani

Way Hotel (Merina Ahmed Tower), Uttara, Dhaka

Omni Properties Ltd

Way Hotel

Lakeshore Hotel Gulshan

Lakeshore Hotel Gulshan, Dhaka

Omni Properties Ltd., Banani

Way Hotel (Merina Ahmed Tower), Uttara, Dhaka

Omni Properties Ltd

Way Hotel

Lakeshore Hotel Gulshan

Asian Duplex City, Sylhet

Anwara Group (Personal Project), Bashundhara R/A

Asian Duplex City, Sylhet

Anwara Group (Personal Project), Bashundhara R/A

Rotary Apu Munshi Memorial Trust General & Cancer Hospital., Rangpur

SICHO Arena Sports Complex, Kalurghat, Chattogram

CCDB – Climate Technology Park by NGO, Gazipur

Rotary Apu Munshi Memorial Trust General & Cancer Hospital., Rangpur

SICHO Arena Sports Complex, Kalurghat, Chattogram

CCDB – Climate Technology Park by NGO, Gazipur

FAQ Questions

You are a product of your environment. So choose the environment that will best develop you toward your objective. A market is never saturated with a good product, but it is very quickly saturated with a bad one.

AAC is a light porous silicate product made mostly of siliceous materials (sand) and calcareous materials (lime, cement), with gas-forming admixtures (aluminum powder) as the principal addition agent.

It is a non load bearing masonry unit which is best for partition walls solution and exterior wall solution.

AAC blocks are manufactured through a precise process. First, a slurry is prepared by mixing cement, lime, water, sand, and a small amount of aluminum powder. This mixture is poured into molds and allowed to rise. The aluminum powder reacts with lime and releases hydrogen gas bubbles, causing the mixture to expand. The blocks are then cured in autoclaves at high temperatures and pressure, resulting in strong and durable AAC blocks.

There are several advantages of using AAC blocks:

- Cost Effective & Easy to Use

- Reduce dead load of a building

- Light-Weight but Durable

- Ensure Dimensional Accuracy & less Wastage

- Ensure Faster Construction

To know in detail please visit (AAC Block Page-Feature & Advantages Section)