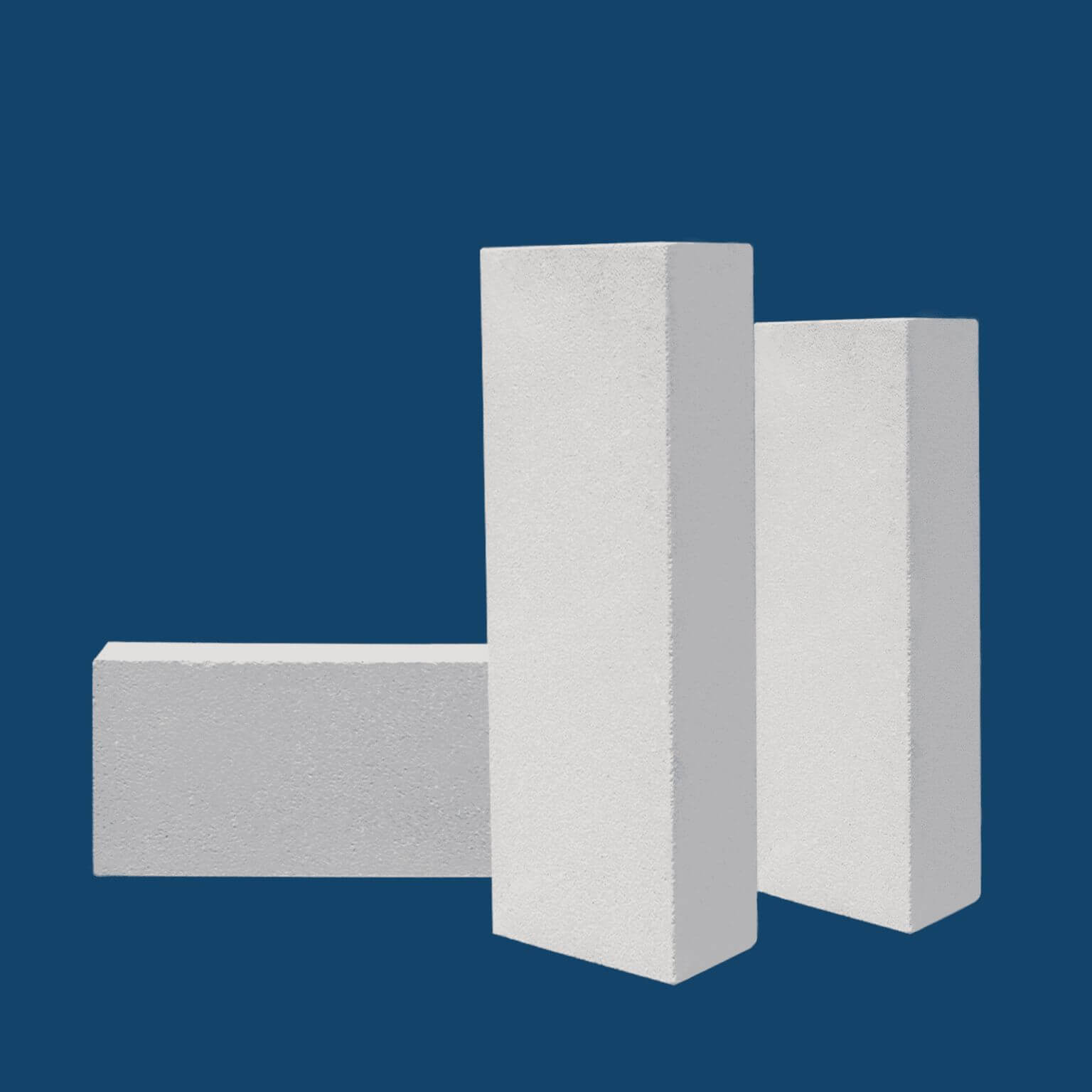

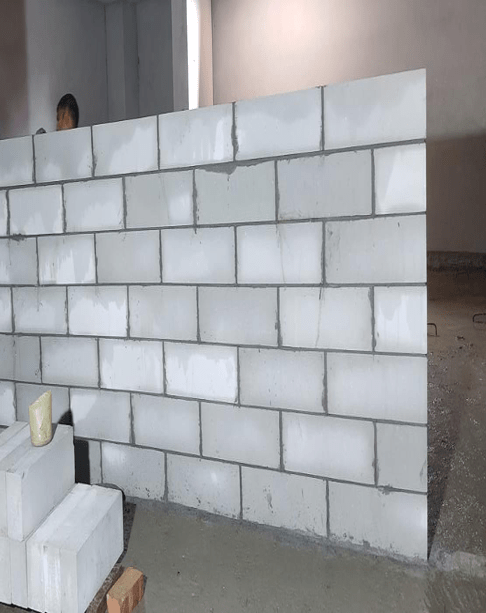

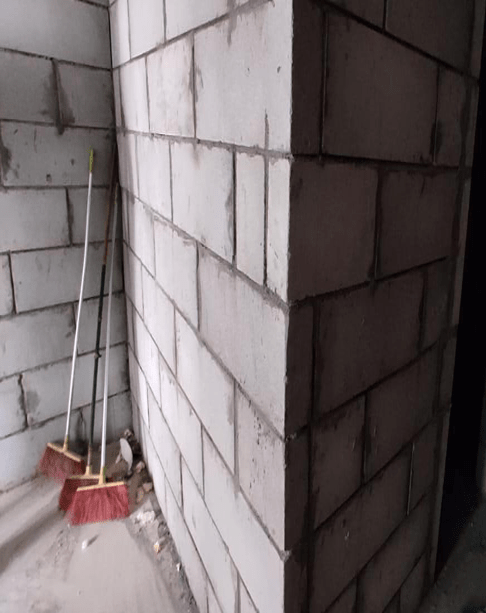

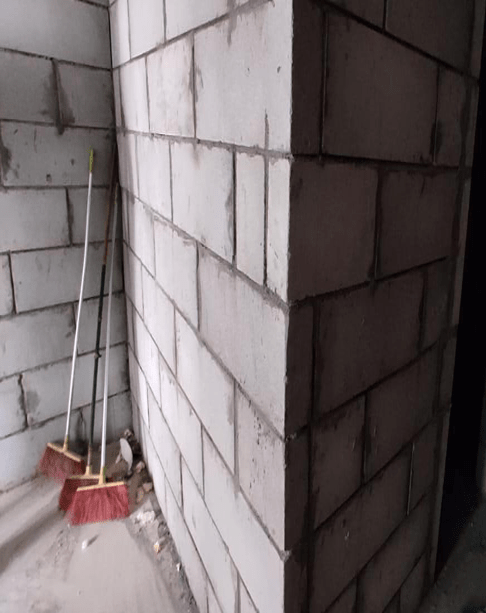

AAC Block

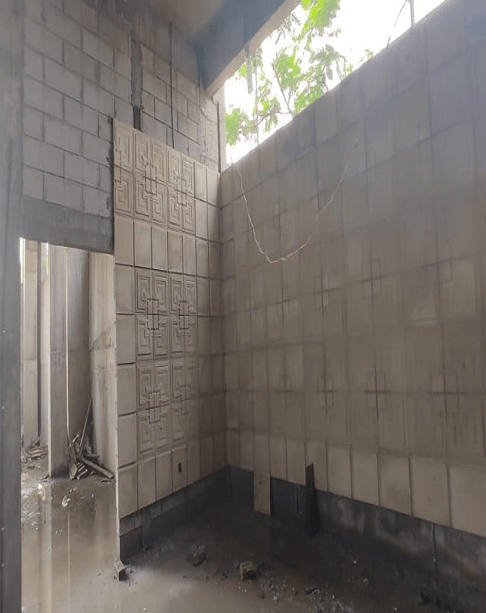

The AAC block’s basic raw material is sand added with cement, lime, gypsum, aluminum powder & other additives. It’s a non-loadbearing masonry unit which is best for any Kind of wall solution. Choose our high-quality AAC blocks for your next construction project and participate in the green revolution.

Years of Legacy

AAC Projects

Clients

Features & Advantages

For being a technologically advanced product, Nextblock-Autoclaved is offering some fundamental features & advantages to its users.

Certificate

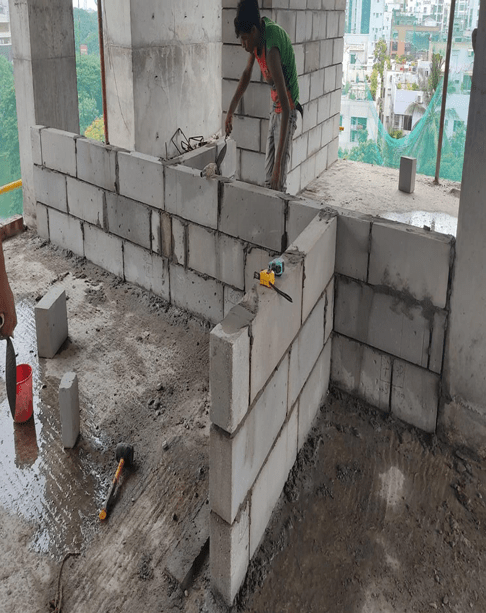

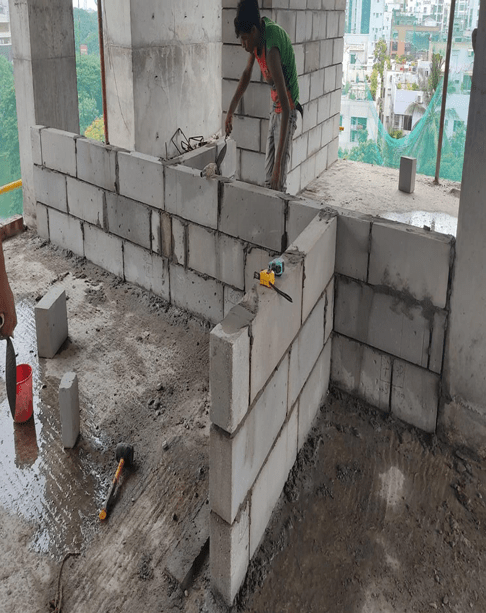

Faster & Easy Construction

Can increase the work speed into 2 times with easy installation

Certificate

Light-Weight

40% Lighter than Traditional Bricks . so it reduces the deadload of a building

Certificate

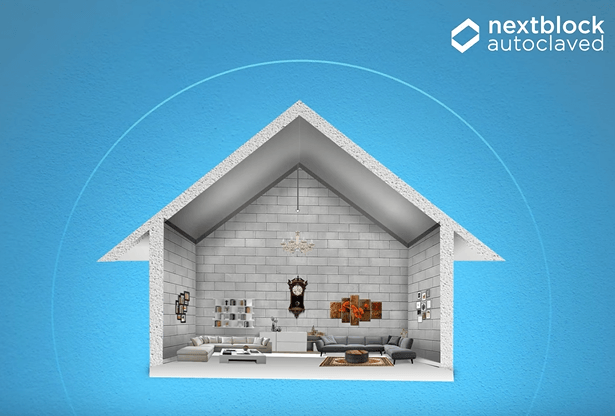

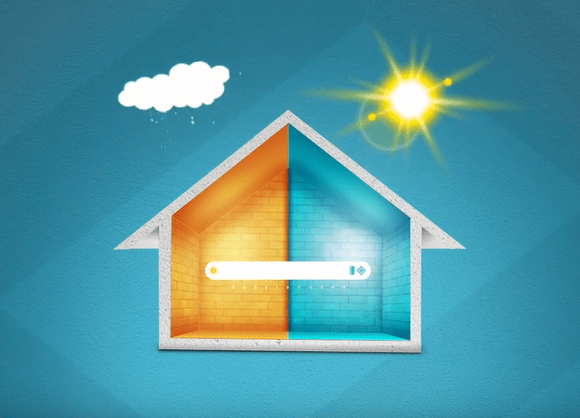

THERMAL INSULATION

Maintain Indoor Temperature, get advantage of 5 Degree Celsius in both Summer & Winter

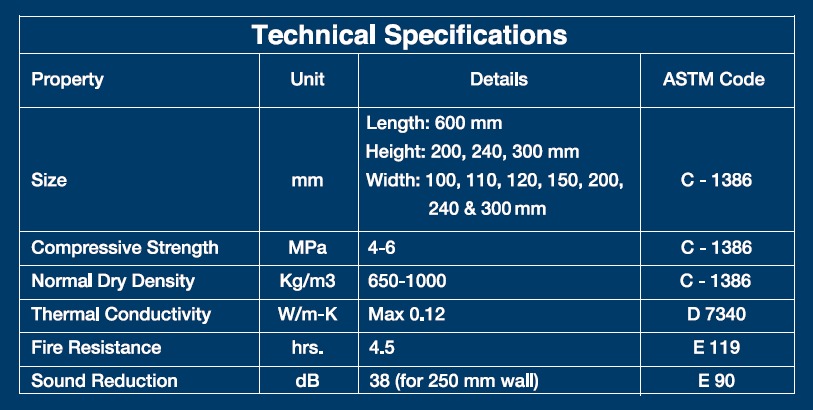

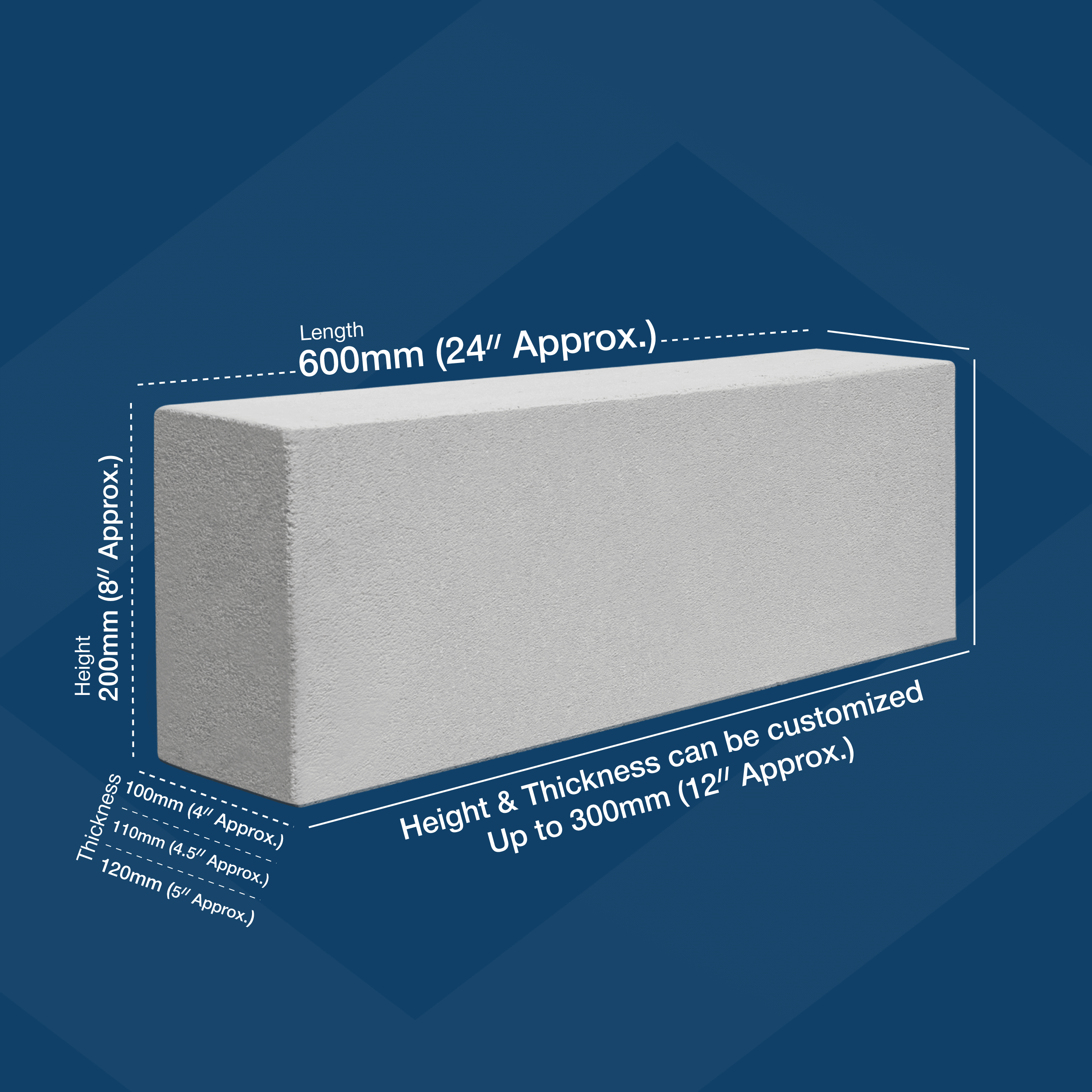

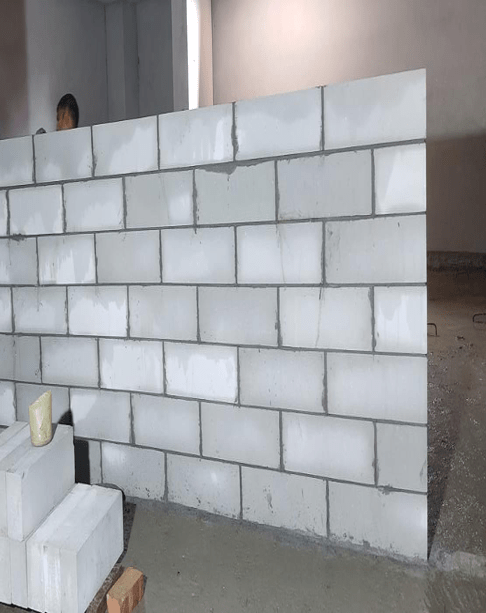

Product Size & Specifications

Our AAC blocks come in various sizes to suit different construction needs. Standard sizes include 600x200x100mm, 600x200x150mm, and 600x200x200mm. Custom sizes can also be provided as per customer requirements.

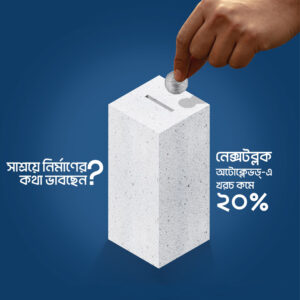

How Do AAC Blocks Save cost?

Using AAC blocks can reduce overall construction cost up to 20%

- AAC blocks are very affordable in price

- For being light-weight AAC blocks reduce foundation cost

- One AAC block is equivalent of 7 red bricks in size, so it reduces the joint mortar cost

- For being large in size it makes work 2 times faster, saves labor cost

- AAC blocks reduce cement & steel consumption in construction

- The excellent thermal insulation properties of AAC blocks also result in energy savings, reducing long-term operational costs.

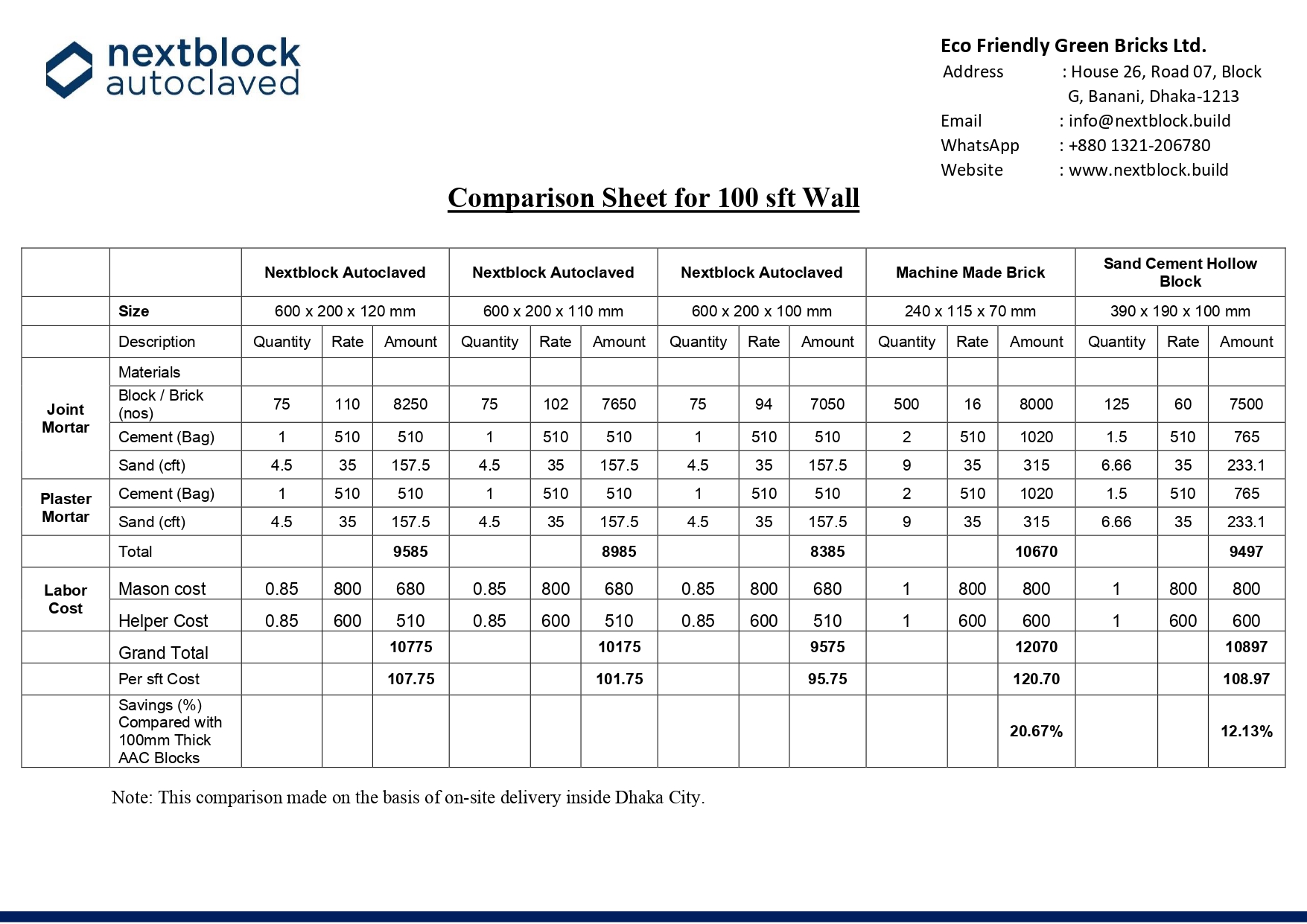

Comparison For 100 sft Wall

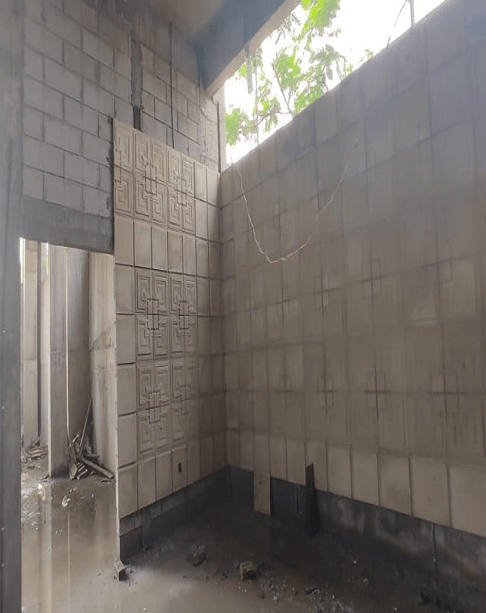

AAC Block Application Guide

Learn how to effectively use AAC blocks for various construction applications. Our guide provides step-by-step instructions and best practices for optimal results.

Drilling & Necessary Installments on AAC Block Wall

Watch and Learn how easy it is to install anything on AAC Block’s wall.

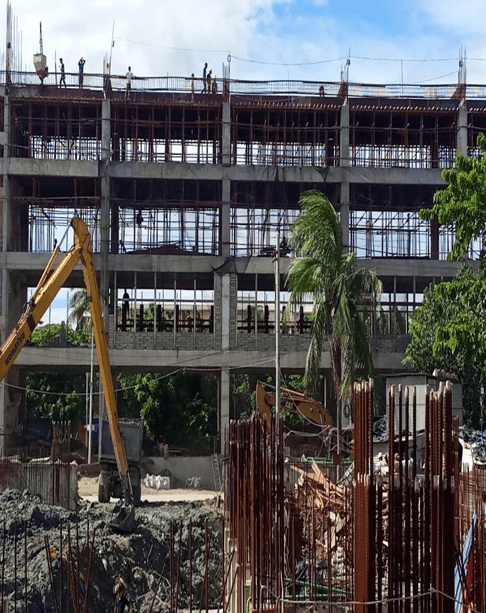

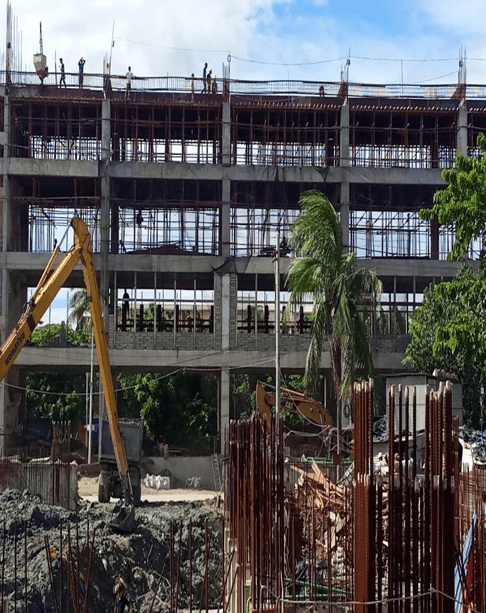

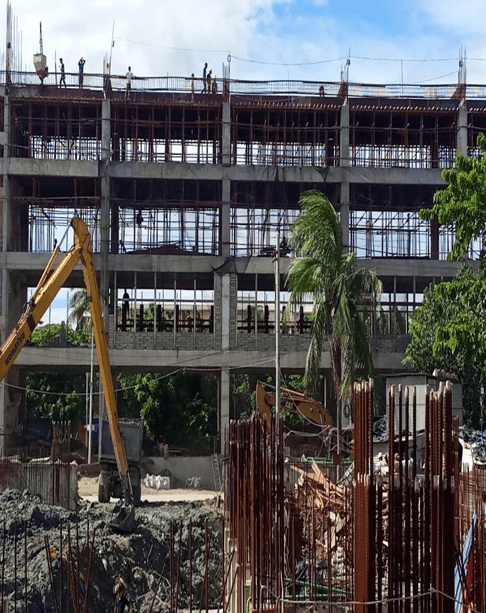

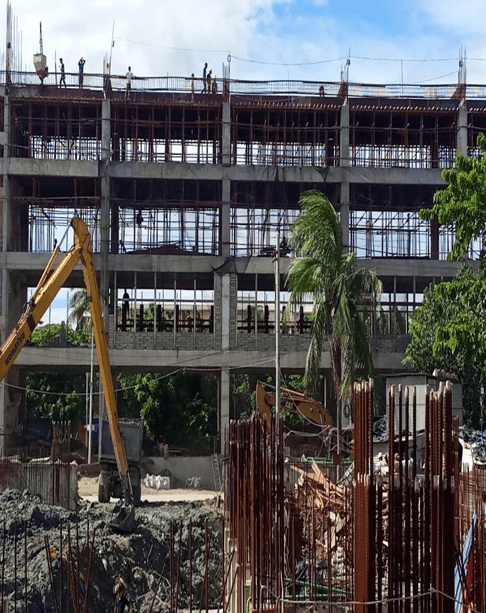

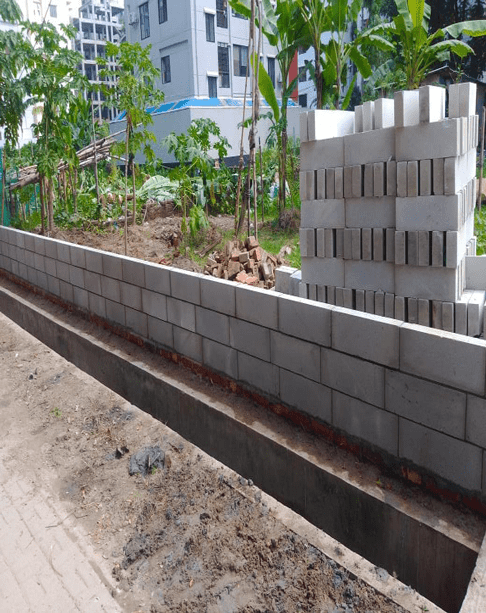

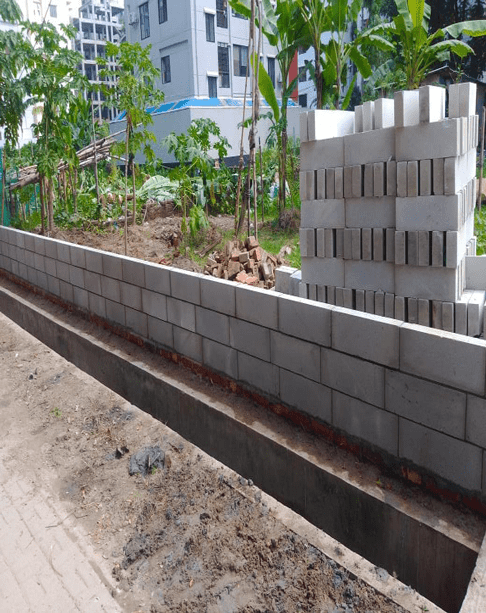

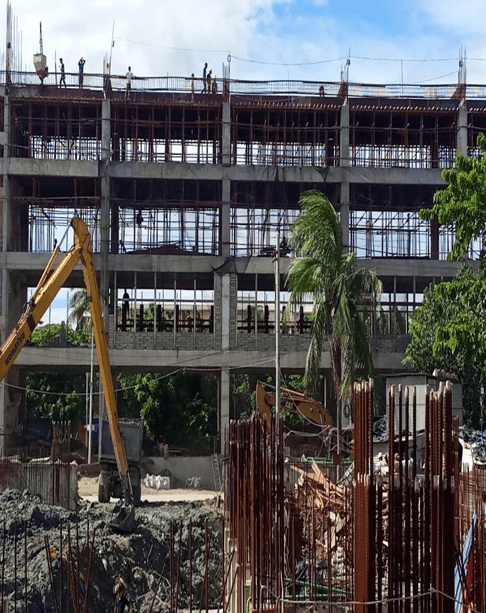

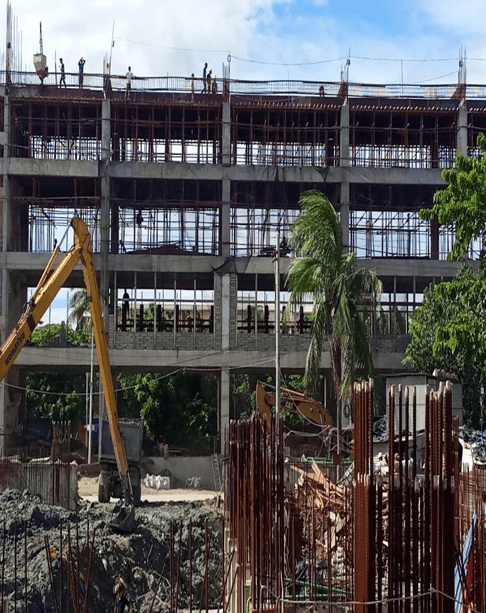

Our Mega Projects

Discover the impressive construction ventures we have undertaken, showcasing our expertise and commitment to excellence in the industry.

United Group – United Tank Terminal

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Bashundhara Sports Complex

Rupayan City

Q-Hotel, Quality Feeds Ltd

Pacific Jeans Ltd

United Group – United Tank Terminal

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Bashundhara Sports Complex

Rupayan City

Q-Hotel, Quality Feeds Ltd

Pacific Jeans Ltd

3 Sign Engineering

Tensile Architecture BD

Bosoti Realestate

DATASOFT

Ventura Properties Ltd

CDL-Residential Project

3 Sign Engineering

Tensile Architecture BD

Bosoti Realestate

DATASOFT

Ventura Properties Ltd

CDL-Residential Project

Delvistaa

Sunflower Restaurant, Food Hall

Delvistaa

Sunflower Restaurant, Food Hall

Omni Properties Ltd

Way Hotel

Lakeshore Hotel Gulshan

Q-Hotel, Quality Feeds Ltd

Omni Properties Ltd

Way Hotel

Lakeshore Hotel Gulshan

Q-Hotel, Quality Feeds Ltd

Pacific Jeans Ltd

Cotton Field

Krishibid Seed Limited

Bengal Hurricane Group

SAM Agro

Pacific Jeans Ltd

Cotton Field

Krishibid Seed Limited

Bengal Hurricane Group

SAM Agro

Enam Medical College

Enam Medical College

Baitun Nur Central Mosque, Sagardighi Bazar

Baitun Nur Central Mosque, Sagardighi Bazar

Karnafuli Fish Meal Ltd

The Oasis, ABC Real-Estate

Edison Real Estate

Cube Holding Ltd.

Bashati Consortium Ltd.

Karnafuli Fish Meal Ltd

The Oasis, ABC Real-Estate

Edison Real Estate

Cube Holding Ltd.

Bashati Consortium Ltd.

CCDB – Climate Technology Park by NGO

United Group – United Tank Terminal

United Group – IPCO Project

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Bashundhara Sports Complex

Residential Project in Green Model Town

CCDB – Climate Technology Park by NGO

United Group – United Tank Terminal

United Group – IPCO Project

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Bashundhara Sports Complex

Residential Project in Green Model Town

Residential Project

Residential Project

Residential Project in Green Model Town

Residential Project

Residential Project

Residential Project

Residential Project in Green Model Town

Residential Project

United Group – United Tank Terminal

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Bashundhara Sports Complex

Rupayan City

Q-Hotel, Quality Feeds Ltd

Pacific Jeans Ltd

United Group – United Tank Terminal

Japan-Bangladesh Retirement Homes (AWR & CPDL)

Bashundhara Sports Complex

Rupayan City

Q-Hotel, Quality Feeds Ltd

Pacific Jeans Ltd

FAQ Questions

You are a product of your environment. So choose the environment that will best develop you toward your objective. A market is never saturated with a good product, but it is very quickly saturated with a bad one.

AAC is a light porous silicate product made mostly of siliceous materials (sand) and calcareous materials (lime, cement), with gas-forming admixtures (aluminum powder) as the principal addition agent.

It is a non load bearing masonry unit which is best for partition walls solution and exterior wall solution.

AAC blocks are manufactured through a precise process. First, a slurry is prepared by mixing cement, lime, water, sand, and a small amount of aluminum powder. This mixture is poured into molds and allowed to rise. The aluminum powder reacts with lime and releases hydrogen gas bubbles, causing the mixture to expand. The blocks are then cured in autoclaves at high temperatures and pressure, resulting in strong and durable AAC blocks.

There are several advantages of using AAC blocks:

- Cost Effective & Easy to Use

- Reduce dead load of a building

- Light-Weight but Durable

- Ensure Dimensional Accuracy & less Wastage

- Ensure Faster Construction

To know in detail please visit (AAC Block Page-Feature & Advantages Section)